The standard square shaft piles are usually installed using compact equipment, like a skid-steer loader or excavator with hydraulic drive heads. This approach not only allows for faster installation but also eliminates the need to prepare the ground thoroughly. Operators play a vital role in ensuring that the piles are placed in a straight line by using visual signals and the assistance of ground personnel.

One of the most important elements of helical pile installation is achieving the capacity of load you want to achieve. This is where the correlation between installation torque as well as load capacities is essential. Modern torque indicators, such as the Chance Digital Torque Indicator, are crucial to this process, offering accurate measurements, and removing the uncertainty associated with estimates of pressure in hydraulic systems.

The operating speed during installation is critical, typically ranging between 8 and 16 RPM. This controlled speed will ensure that the pile is moving about three inches each revolution consistent with the pitch of the helical plates. If the pile doesn't advance as expected, adjustments like increasing downward thrust or adding larger plates to prevent'spinning out', akin to a screw stripping its threads.

Multi-scale study of load-bearing mechanism of uplift piles based on model tests and numerical simulations | Scientific ... Nature.com

Posted by on 2023-04-19

Heerema Marine Contractors Develops Concepts for Silent Foundations Society of Petroleum Engineers

Posted by on 2021-01-27

Every Deck Starts with Good Footings Fine Homebuilding

Posted by on 2016-06-17

Transmission Construction: Micropile-Grillage Base Works in Virginia's Mountains T&D World

Posted by on 2023-05-31

VersaPile a versatile helical steel pile contractor in Manitoba - constructconnect.com Daily Commercial News

Posted by on 2023-10-02

Safety put 'in jeopardy' by some companies shoring up shaky homes, industry complaint alleges CBC.ca

Posted by on 2019-06-23

Getting the Basics Right: Ground Screws vs. Driven Piles Solar Builder Magazine

Posted by on 2022-01-20

Boardwalk Construction Bids Face Legal Challenge | Sandwich News | capenews.net CapeNews.net

Posted by on 2023-03-30

The construction industry is always seeking innovative solutions to enhance efficiency, reduce costs, and ensure structural integrity. In this pursuit, helical piles have emerged as an innovative technology revolutionizing how we approach foundational support.

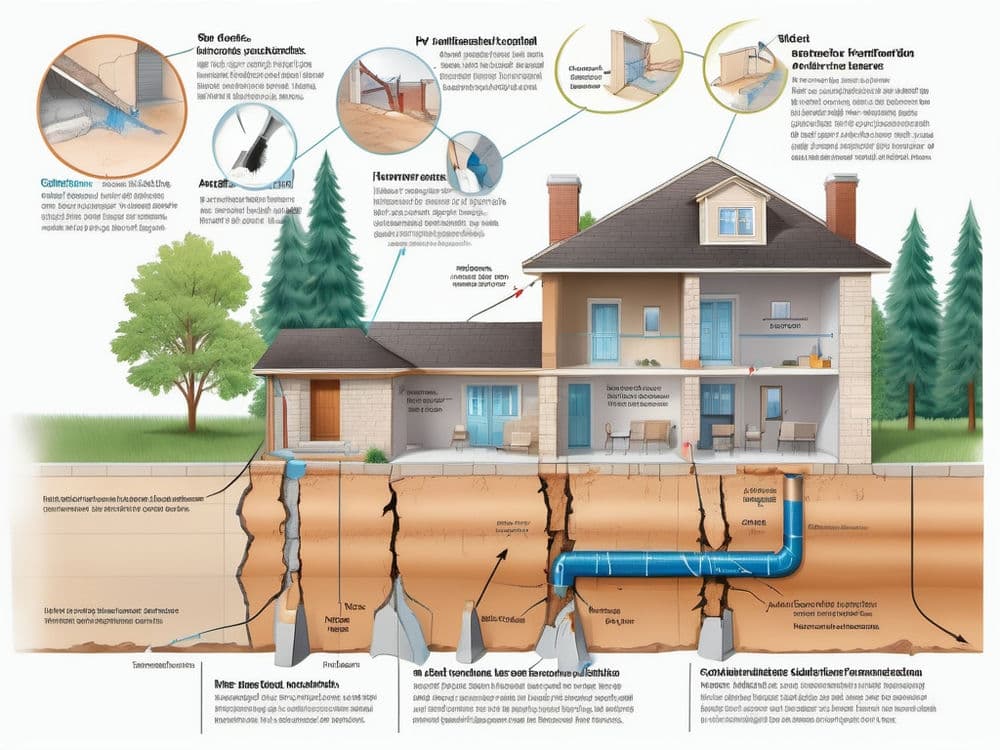

Helical piles, sometimes called screw piles, are deep foundation solutions that are used to secure new or repair existing foundations. They are made from steel, and come with an helical lead section which allows they to go into the ground much like a screw into wood. This design is a significant change from conventional concrete foundations, offering several advantages that cater to modern requirements for construction.

Helical piles, sometimes known as screw piles, are one type of deep foundation system consisting from a shaft central with some or all of the blades that resemble helix shapes. This design allows the screw to be inserted to the earth, providing a secure and stable foundation for various types of structures. Based on the 19th century inventions of Irish engineer Alexander Mitchell, helical piles have evolved and are now in the forefront of contemporary foundation technology.

One of the standout advantages of helical piles are their speed and ease of installation. Unlike traditional concrete foundations, which require significant excavation and curing Helical piles can be quickly installed using hydraulic machinery. This not only accelerates the process of construction but also reduces their impact on natural environment. The less need for huge excavation areas makes them particularly beneficial in urban areas or in areas with environmental concerns where the preservation of natural landscapes is essential.

Alongside their main advantages, helical piles come with a range of additional advantages that solidify their position in modern construction. These include:

These additional features, coupled with their main benefits they make the helical piles an extremely versatile and effective foundation choice for a wide range of construction projects.

Versatility is a key attribute of Helical piles. They can be adapted to a range of soil kinds and conditions, making an excellent choice for a range of projects, ranging from residential buildings to industrial structures. Their design can be tailored to suit specific load requirements, enhancing their applicability across various construction scenarios.

Helical piles also have the advantage of immediate load bearing capacity. Once installed, they can support loads right away, a significant benefit over traditional methods that need waiting for the concrete to cure. This feature is especially useful for projects that have tight deadlines or in emergency situations when time is crucial.

Lastly, the sustainability of helical piles can't be overlooked. They are usually made from recyclable steel, and they are accessible, which allows for reuse in subsequent projects. This reuse, along with their reduced carbon footprint during installation is in line with the growing emphasis on eco-friendly construction practices.

In conclusion the hidden advantages of Helical pile installation - speed, minimal environmental impact, flexibility, immediate load capacity, and their sustainability - account for their increasing popularity in the construction sector. In the ongoing effort to search the most efficient, cost-effective and environmentally responsible building methods, helical piles are a strong, innovative solution to today's construction challenges.

Building on the foundational strengths of the helical piles and their usage in construction projects provides a number of specific advantages.

These factors highlight the many benefits of the use of the helical piles and highlight their importance in improving efficiency, sustainability and efficiency in construction.